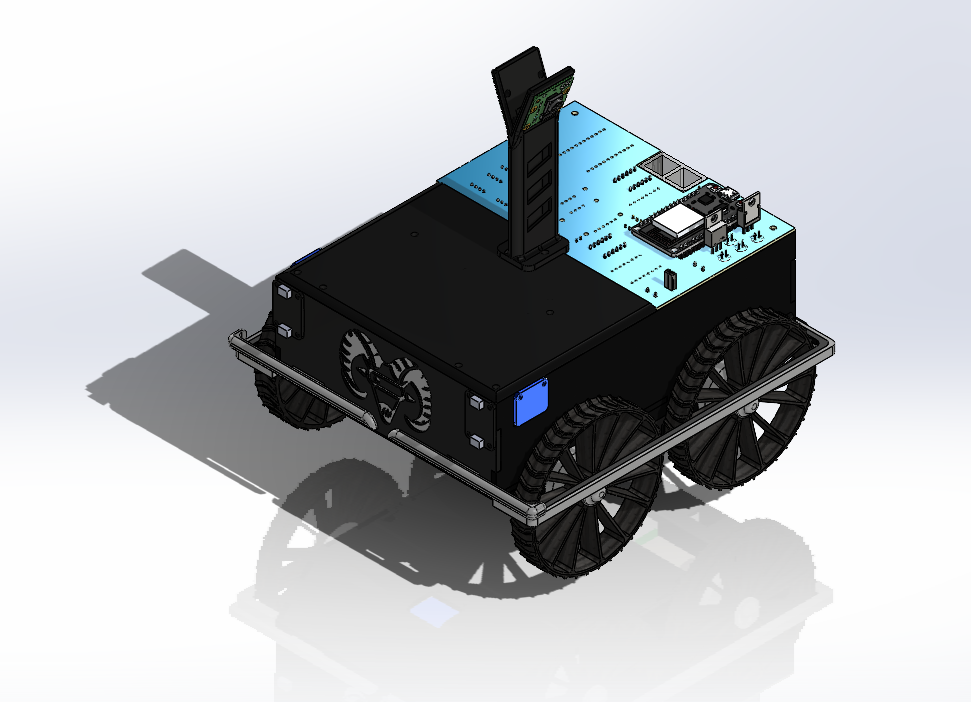

Overall CAD

The entire robot was designed from scratch using SolidWorks so that each element along with all the components to be used were integrated and had their own place.

The chassis was built thinking about making the robot as low as possible but keeping a minimum height of 2cm below its base to be able to pass the speed bumps.

Keep this minimum height and the size of your robot diagonal as important measures to consider when designing the robot

We included a box to storage the batteries, store them at the bottom was useful to lower the center of mass, and not overturning on the ramps. The box was meant to be retractible, a great idea but with bad implementation since the 3D printed part tended to break, at the end we use screws to attached it to the main mdf frame.

Keep in mind mdf is brittle and easy to break, however is rapidly manufactured with the laser cutter, 3D printing although providing more design liberty takes longer to print and to iterate from different designs, remember that it is also heat deformable, a hot jetson maybe enough to deform PLA.

Try to do modular design specially with sensors, although they can always be easily placed with hot glue and making a hole in the chassis, contemplate a modular piece that facilitates the change from different types of sensors (ToF or utrasonic, or from different ToF models) can be a good idea that looks more professional and clean.

Cables always take more space than expected, good communication between electronics and mechanics is essential

Place the color sensor as low and as front as possible