Wheels

General description

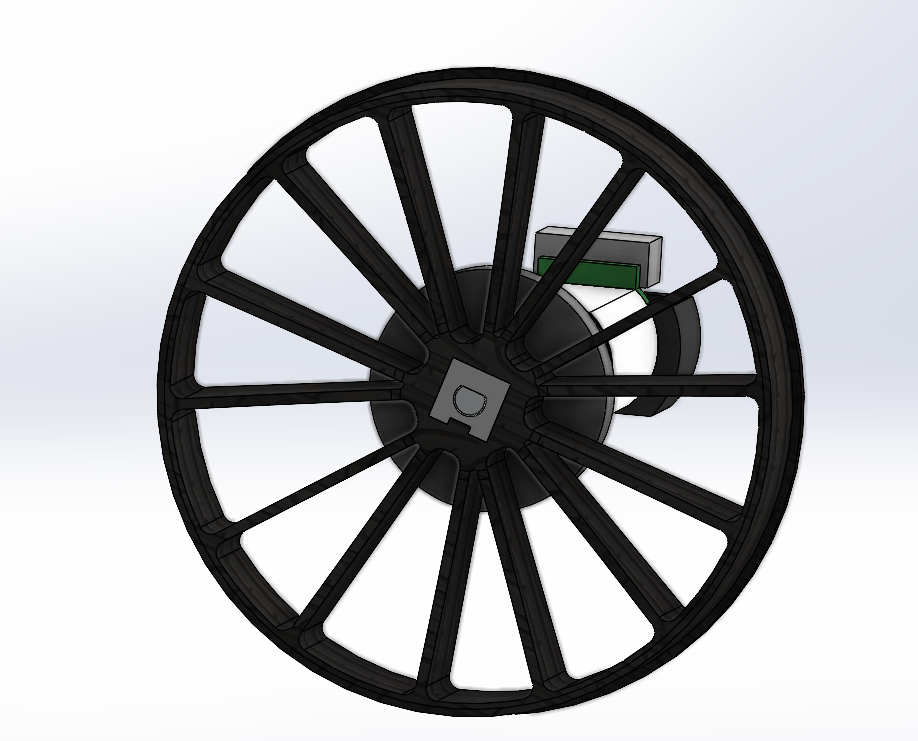

The wheels were made using PLA and silicone. The cental part of each wheel is made of a PLA 3D printed design and the outer part or the tire was made using silicone and a mold.

The inner design was made keeping in mind some holes in which the silicone could get stuck once it gets dry. Since silicone is not a material that adheres to PLA, this design had to have these apertures so it could keep its shape.

Additionally, this inner part leaves a space designated for the motor connector, which is a small part, algo PLA, that helps connect the motor to the wheel. This connector was designed to fit with minimal clearance and includes holes for M2 screws. The purpose of making this connector a separate part from the main wheel was to allow for as many design iterations as needed. It was also important that it be replaceable in case it wore out from extensive use.

For the silicon mold, the thickness of the tire was changed for the regional and national competition. For the regional competition it was thicker, which presented some issues (described below), and for the national competition it was way slimmer, allowing for a better grip of the silicone, not only to the surface but also to the PLA.

A simple pattern was made in the mold to be able to allow for a better grip. The first iteration of the mold also included a cover that had screw holes, but this method was discarded since a simpler way to put pressure of the PLA was found, which was just to add weight on top. Also, the cover made the process messier since the silicone started to leak and there was no way to see exactly what was happening and how it was setting in the PLA.

The process consisted of printing both the mold and wheel, then the mixture of the different types of silicone (type A and B) and then inserting it into the mold with the wheel inside. A certain amount of weight needed to be put into the PLA, so the silicone would stay in place while it got dry. The process of drying took anywhere from 12 – 24 hours.

Challenges

For the regional competition, most of the difficulties that were faced were in relation to the silicone tire. Sometimes, due to the great thickness, it could get stuck in an external object causing some part of the tire to slip out of the PLA. For the national competition, this was fixed making the tire slimmer as was mentioned above.

Regarding the motor connector, several issues also arose. Over time and with use, they would begin to wear down, which caused the wheels to loosen. To solve this, the center piece was simply replaced whenever signs of loosening appeared. It also became clear that the fit between the connector and the motor depended on the material used and the orientation in which it was printed. The optimal printed position was found to be on the side and with Hatchbox PLA, but also Polymaker PLA seemed to adjust well. A different PLA could also be used, but the clearance would probably need to be adjusted.